You’ll want evidence, not marketing, when choosing a mixer grinder that lasts: look for measured MTBF, thermal‑cutout behavior, sealed bearings, corrosion‑resistant shafts, and service access points. Focus on common failure modes — overheating, seal leaks, switch wear — and how quickly parts are available regionally. I’ll walk you through what to verify, which specs matter most, and the exact questions to ask to avoid surprises.

Key Takeaways

- Check enclosure materials, joint tolerances, sealed bearings, and documented thermal management for mechanical and thermal durability.

- Verify motor specs: torque/load curves, insulation/IP rating, MTBF data, and expected power loss after heavy use.

- Confirm warranty details: duration, components covered, claim process, authorized centers, and voiding conditions.

- Assess repairability: modular housings, accessible fasteners, standard screws, and presence of service manuals.

- Ensure spare-parts availability: SKU continuity ≥5 years, regional stock within 48–72 hours, and lead-time guarantees.

What Makes a Mixer Grinder Last: Key Build‑Quality Indicators

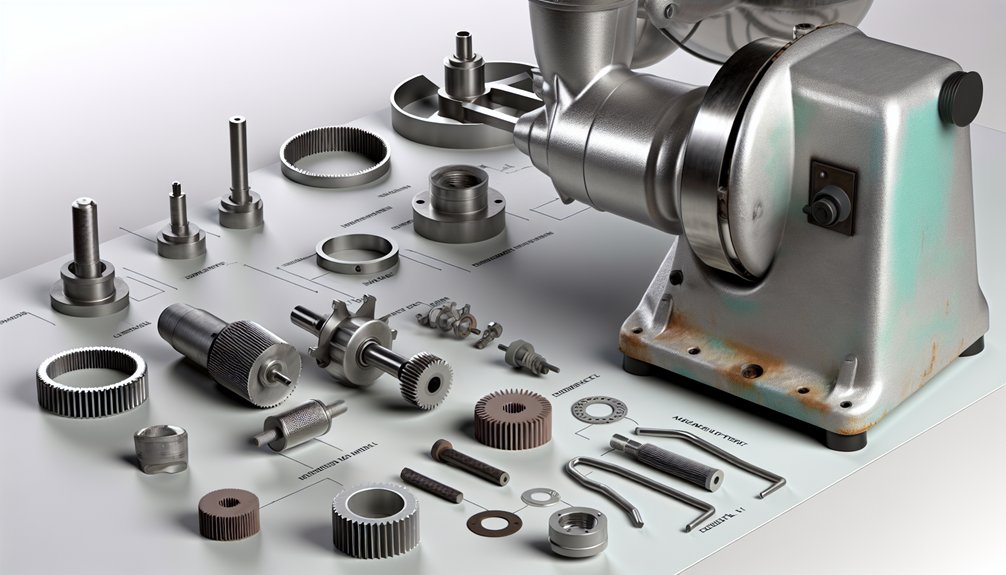

What actually determines whether a mixer grinder will still be running reliably in five years? You’ll evaluate enclosure materials, joint tolerances, and thermal management metrics first. Check rated IP/insulation class, torque/load curves under stall conditions, and documented MTBF or component life tests. Inspect switch and bearing designs: sealed bearings, metal shaft couplings, and replaceable bushings reduce catastrophic failure risk. Verify wiring gauge, heat-shrink terminals, and UL/IS safety markings to prevent electrical faults. Look for service-friendly assembly: modular housings, accessible fasteners, and standard screw types to enable safe repairs. Demand parts lists and part-numbered schematics from vendors; absence predicts longer downtime. Prioritize units with quantified failure rates, replacement-part availability, and clear safety certifications to minimize hazardous failures. Also verify that motors are commercial-grade (750–1500 W) with thermal overload protection for continuous hotel or small-business use.

Motor Durability and Performance Over Time

How will a motor’s performance trend after years of regular use? You’ll see measurable declines: power loss of 10–30% is common after 3–5 years under daily heavy loads, primarily from brush wear, bearing degradation, and insulation breakdown. Run-time data show increased current draw and vibration spikes before failure; a 15% current rise often precedes thermal cutouts. Inspect brush length, bearing play, and winding resistance periodically — rising resistance (>10% above baseline) signals insulation aging and overheating risk. Failure modes include stuck rotors, commutator pitting, and oil-contaminated bearings; each raises safety hazards like short circuits and fire. Plan preventive maintenance intervals, replace brushes and bearings proactively, and document torque and ampere readings to detect deterioration before catastrophic failure. Choose a model with thermal overload protection and sturdy stainless-steel components to reduce long-term wear and service needs.

Warranty Fine Print and Manufacturer Support Networks

Why does the warranty language matter as much as the hardware? You’ll want quantified coverage: length (years), components covered (motor, electronics, jars), and conditional clauses (use-case limits, voltage, accidental damage exclusions). Inspect claim procedures: authorized center list, turnaround times, required proof, and cost caps for diagnostics. Pay attention to void triggers—unauthorized repairs, non‑standard blades, or commercial use—that correlate with higher failure rates in field data. Evaluate manufacturer support networks by density of service centers per region and official technician certification rates; sparse networks increase downtime and safety risk from DIY fixes. Keep records; documented maintenance often preserves claims. Choosing explicit, enforceable warranty terms plus robust support minimizes hazardous failures and ensures predictable remediation. Also, longer, clearer warranties and good service networks reduce expected repair and replacement costs over the appliance’s lifetime, so check the warranty length when comparing models.

Evaluating Repairability and Spare‑Parts Availability

Having clear warranty terms and a dense service network only gets you so far if the unit’s parts aren’t accessible or its design prevents practical repairs. You should quantify common failure points—motors, bearings, seals, switches—and check parts-obsolescence rates: request manufacturer lead times and SKU continuity for at least five years. Inspect fastener types, modular assemblies, and whether components are soldered versus plug‑in; these predict mean-time-to-repair and technician safety. Track repair-success rates and average downtime from service centers; a high failure recurrence signals design or parts-quality issues. Verify availability of critical spares (motor, coupling, jar, gasket) regionally; backorder frequency above 10% materially increases risk. Prioritize models with documented parts diagrams, safety interlocks that are replaceable, and clear service manuals to reduce hazardous improvisation. Also ensure the machine includes reliable overload protection to prevent motor and winding damage during heavy use.

Practical Questions to Ask Before You Buy

What specific failure modes and repair timelines should you plan for before buying a mixer grinder? Start by listing common failures: motor burnout, bearing wear, capacitor failure, switch and wiring faults, seal and gasket degradation. Ask the dealer for MTBF estimates, typical time-to-repair, and parts lead times for each failure mode. Request documented failure rates or warranty claim statistics and local stock levels for motors, switches, and seals. Confirm whether certified technicians and OEM parts are available within 48–72 hours in your area. Verify safety-related inspections, thermal cutout replacement procedures, and whether the unit has accessible service panels to reduce repair time. Prioritize units with modular components and clear service manuals to minimize downtime and safety risk. Also consider choosing a unit with an appropriate wattage rating to match your usage patterns and reduce the likelihood of overheating or premature motor wear.

Frequently Asked Questions

Can Dishwasher Use Ruin Mixer Grinder Parts?

Yes — dishwasher use can ruin mixer grinder parts. You’ll risk corrosion, warped plastic, degraded seals, and dulled blades from high heat, harsh detergents, and agitation; failure rates rise, shortening service life and requiring earlier replacements.

Are Aftermarket Jars Compatible With All Brands?

No, aftermarket jars aren’t universally compatible; you’ll often face mismatched couplings, seal sizes, blade fits, or material weaknesses. Check model-specific dimensions, torque ratings, and safety certifications to avoid leaks, motor strain, or injury.

Do Mixer Grinders Affect Kitchen Electrical Wiring Safety?

Yes — they can. High-start currents, poor grounding, frayed cords or overloaded circuits raise fault and fire risks; you should measure draw, ensure dedicated circuits, proper earthing, intact insulation and regular inspections to mitigate failures.

Is Noise Level Linked to Long‑Term Damage?

Yes — persistent excessive noise often signals mechanical wear, imbalance, or bearing failure, and if ignored you’ll accelerate component fatigue, overheating, and motor damage; monitor decibels, inspect seals/bearings, and service promptly to reduce long‑term risk.

Can Frequent Spice Grinding Void the Warranty?

Yes — it can. Manufacturers often exclude heavy-duty or commercial use like frequent spice grinding; repeated overheating, motor strain or abrasion documented in service logs can void warranty, so check terms, duty cycle limits and recommended accessories.