You’ve probably seen how simple hand-cranked grinders gave way to powerful electric mixer grinders that speed up Indian cooking. Over time motors, safety cut-offs, better blades, noise damping and food‑grade jars made them more reliable and versatile. Manufacturers also tuned features for regional tastes and budgets. There’s more to the story—how engineering, regulation and consumer habits shaped today’s models.

Key Takeaways

- Early hand-cranked grinders gave way to electric motors, dramatically increasing speed and domestic throughput.

- Motor innovations (brushless designs, better windings, cooling) improved efficiency, durability, and performance.

- Safety features like overload protectors, thermal cut-offs, interlocks, and insulated wiring became standard.

- Design and materials evolved to ABS shells, stainless steel blades, vibration damping, and noise-reduction measures.

- Multi-function jars, modular accessories, and localized manufacturing made versatile, affordable, serviceable mixers widely available.

Early Mechanical and Hand-Cranked Grinders to Electrification

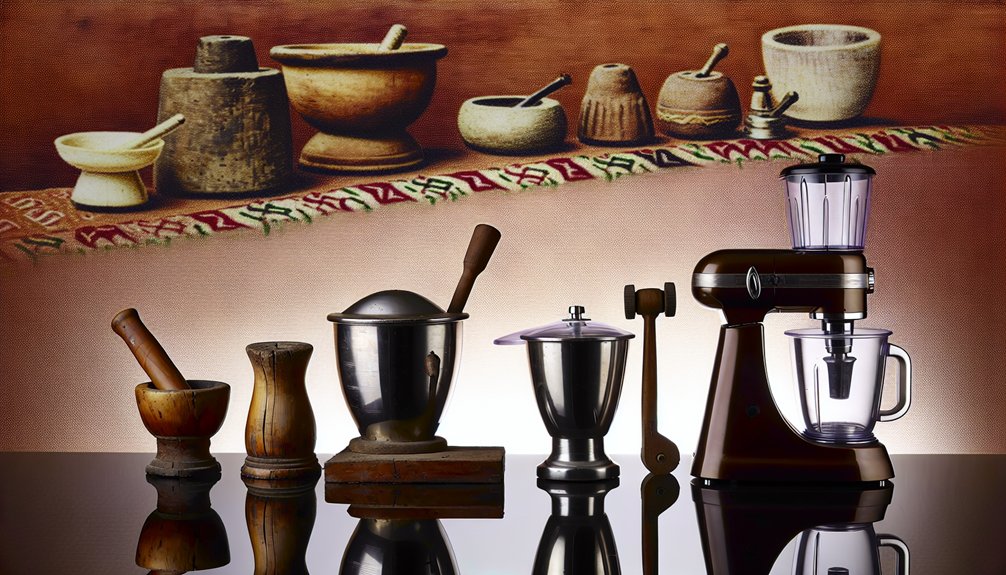

Remember how grinding once meant steady elbow grease? You’d turn a hand-cranked mill, feeling the rhythm as grains or spices were reduced manually. Early mechanical grinders used simple gears and burrs, built for durability and easy maintenance. As electrification spread in India, you saw a practical shift: motors replaced cranks, speed increased, and throughput rose, letting households save time and effort. You’d still appreciate robust construction—metal bowls, tight seals, straightforward disassembly—so cleaning and safe handling stayed manageable. Trends moved toward compact, energy-efficient units that matched inconsistent power supplies. Through this phase, safety meant stable bases, insulated wiring, and secure lids; those basics reduced accidents and set the stage for later innovations without sacrificing reliability. Modern units often incorporate thermal overload protection to prevent motor damage during heavy or continuous use.

Rise of Motor Innovations and Safety Features

As motors became the heart of Indian mixer grinders, you saw rapid improvements in power, efficiency and control that changed how kitchens handled tougher tasks. You noticed brushless motors, improved copper windings and better cooling that raised durability and reduced stalls when grinding dense ingredients. Variable-speed inverters and soft-start circuits gave you finer control and prevented sudden torque shocks. Safety advanced in parallel: overload protectors, thermal cut-offs and automatic shut-offs reduced fire and motor-burn risks, while child-locks and interlock systems stopped the motor unless jars were properly secured. Modern motors also meet efficiency standards, lowering energy use and heat. These innovations make your appliance safer, more reliable and better suited to daily Indian cooking demands. Manufacturers like Philips have emphasized sturdier ABS shells and robust service networks to support these motor and safety improvements.

Design Improvements, Materials and Noise Reduction

How has mixer-grinder design evolved to be more user-friendly, durable and quiet? You’ll notice sleeker ergonomics, anti-slip bases and guarded switches that reduce accidents and make daily use safer. Manufacturers now use stronger, food-safe polymers and stainless alloys to resist wear and contamination, extending life while keeping maintenance easy.

- Improved materials: reinforced ABS, BPA-free plastics and corrosion-resistant steel for hygiene and longevity.

- Vibration control: balanced blades and dampened motor mounts that cut wobble and reduce wear.

- Noise reduction: acoustic insulation, precision gears and slower-start motors that lower decibel levels without sacrificing performance.

These trends prioritize safety and durability, so you get reliable, quieter appliances that fit modern kitchens and cautious households. A good choice of jar and blade materials, such as stainless steel blades, further enhances performance and longevity.

Multi-Function Jars and Convenience-Focused Accessories

Looking for more versatility from a single appliance? You’ll find multi-function jars have transformed mixer grinders into compact kitchen systems. Manufacturers now offer jars for wet grinding, dry grinding, chutneys, juicing and even kneading, so you won’t need separate machines. They use durable, food-grade materials and secure locking lids to reduce splash and contamination risk. Accessories like spatulas, anti-slip bases and measured lids add convenience while supporting safe handling. You should check for easy-fit blades, balanced rotors and clear maintenance instructions to avoid wear or injury. Trend-wise, modular designs let you swap jars quickly and store them neatly, saving counter space. Prioritize certified, warranty-backed units and follow safety guidelines for long-term reliability. Remember that mixer grinders typically handle smaller soaked-grain batches than wet grinders, so plan batch sizes accordingly.

Market Forces, Affordability and Localized Manufacturing

Why has affordability become the dominant lens through which Indian consumers evaluate mixer grinders today? You’re looking for value, safety, and reliable performance amid tight budgets and rising living costs. Localized manufacturing has driven prices down while improving parts availability and service.

- Local sourcing: shorter supply chains lower costs and ensure spare parts are accessible, so you won’t be left with unsafe, unrepairable appliances.

- Scale and competition: many brands produce affordable models with standardized safety features (thermal cut-offs, stable bases) because you demand both price and protection.

- Policy and skills: government support and skilled local labor cut production costs, letting manufacturers offer safer, certified units at accessible prices. Recent product lines from brands like AmazonBasics and Lifelong demonstrate this trend with affordable certified models that balance performance and safety.

Frequently Asked Questions

Can Mixer Grinders Be Used for Wet and Dry Grinding Simultaneously?

No — you can’t safely grind wet and dry items simultaneously in one mixer grinder jar; you’ll risk cross-contamination, motor strain, and inconsistent texture. Use separate jars or batches, follow manufacturer guidelines, and secure lids tightly.

How Do I Clean and Maintain the Motor Safely at Home?

You clean and maintain the motor safely by unplugging, wiping exterior with a damp cloth, not immersing, blowing out dust with compressed air, checking wiring for damage, tightening mounts, and scheduling professional servicing yearly to avoid overheating and faults.

Are There Energy-Efficient Mixer Grinders With Inverter Compatibility?

Yes — you can get energy-efficient mixer grinders with inverter compatibility; they use brushless or efficient induction motors, low-wattage settings, and thermal protection. You’ll save power and stay safer during voltage fluctuations and outages.

What Warranty and After-Sales Services Are Common in India?

You’ll usually get 1–2 year warranties, sometimes extended to 5 years on motors; companies offer in-home repairs, authorized service centers, spare parts availability, and paid annual maintenance plans—check service-network reach and response times for safety.

Can Mixer Grinders Crush Ice or Frozen Ingredients Effectively?

Yes, many modern mixer grinders can crush ice or frozen ingredients, but you’ll need high-power motors, sturdy stainless-steel jars, and blade-duty ratings; always follow manufacturer guidelines, pulse in short bursts, and use safety locks to prevent overheating.