If your mixer grinder motor stops, start by unplugging it and switching off the circuit so you don’t get a shock. Check the power cord, remove jars and blades, and look for obvious jams or burnt smells. You’ll want to cool the unit and clean the coupling before trying to run it again. There are simple tests and maintenance steps you can do safely at home — and clear signs that mean you should call a technician.

Key Takeaways

- Immediately unplug the mixer grinder, switch off the circuit, and wait 60 seconds for capacitors to discharge.

- Inspect the power cord, plug, and plug sockets for cuts, melting, or loose connections before any further testing.

- Clean jar coupling and blade assembly; ensure jars and lids are seated correctly to rule out mechanical jams.

- Reset thermal overload by letting the motor cool 30–60 minutes, then try the built-in reset button if available.

- If you detect burning smells, sparking, seized rotor, or repeated electrical faults, stop and consult a qualified technician.

Immediate Safety Checks Before You Touch Anything

Before you touch the appliance, cut power and confirm it’s truly dead: unplug the cord from the wall and turn off the breaker if the outlet is on a switched circuit. Next, wait 60 seconds to allow capacitors to discharge. Use a non-contact voltage tester at the plug and motor terminals to verify no live voltage. Inspect the cord for cuts, exposed conductors, or melted insulation; replace the cord before any further work. Remove bowls and blades, securing sharp parts, then lock the motor housing to prevent accidental rotation. Wear insulated gloves and eye protection. Keep water away; dry surfaces reduce shock risk. If you find burned smells, smoke damage, or damaged windings, stop — those require a qualified technician. Also, perform a quick check of seals and gaskets to ensure there are no leaks or damage to critical components check seals.

Simple Fixes You Can Try at Home

Want to try a few quick fixes yourself? First, unplug the unit and wait until moving parts stop. Inspect the jar coupling and blade assembly for food debris or jammed particles; clean with a brush and wipe dry. Check that jars and lids are seated properly—misalignment can prevent motor engagement. Examine the power cord for visible damage; if frayed, don’t use the appliance. Try a different wall outlet to rule out a faulty socket. Reset thermal overload by leaving the unplugged grinder to cool for 30–60 minutes; some models have a reset button you can press once cooled. Tighten loose mounting screws on the base and coupling with an appropriate screwdriver. If the motor still won’t start, stop and seek professional service. Also, make sure the appliance is on a dry, flat surface and the socket is properly grounded before testing again.

How to Test Electrical Components Safely

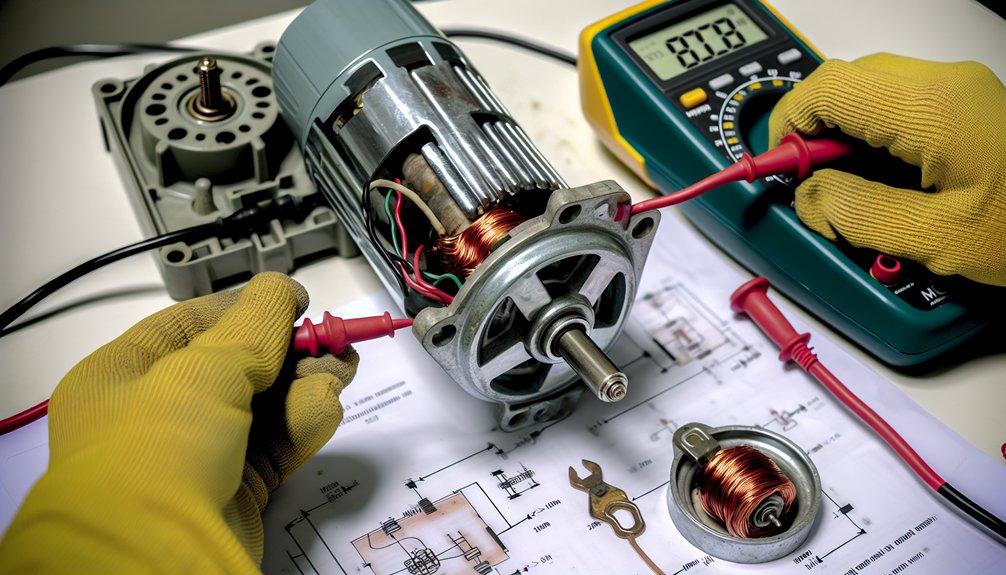

If those quick checks don’t bring the motor back to life, you can move on to testing electrical parts—but only with proper precautions. Shut power, unplug the unit, and discharge any capacitors before touching components. Use insulated tools, wear safety glasses, and keep one hand free from conductive paths. Verify your multimeter is rated for the task and set to the correct function.

- Inspect wiring and connectors for burns or loose crimps; measure continuity across leads.

- Test the power switch and capacitor: continuity for switch positions, capacitance within spec.

- Check motor windings: measure resistance for open or shorted coils; compare to service values.

- Verify earth/ground continuity and insulation resistance to chassis.

Also consider that some Bajaj models include motor overload protection, which can trip and mimic motor failure, so check the unit’s protection features before replacing components.

Routine Maintenance to Prevent Motor Failure

How often should you perform basic upkeep to keep the mixer grinder motor running reliably? You should inspect and clean external vents and the jar coupling after every 5–10 uses; this prevents dust and food buildup that causes overheating. Every month, unplug the unit and check power cord integrity, plug contacts, and the on/off switch for heat damage or looseness. Every 3–6 months, open the housing (if user-serviceable) to remove lint, check carbon brushes for wear, and ensure cooling fan blades rotate freely. Apply a drop of light machine oil to accessible bearings only if the manufacturer permits. Keep load cycles within rated capacity and avoid prolonged continuous operation to reduce thermal stress. Always disconnect power before any maintenance. For heavy prep or frequent large batches, consider using a processor with overload protection to reduce motor strain during bulk work.

When to Call a Professional or Replace the Appliance

When should you call a technician or scrap the unit? If you’ve run basic checks (power, fuse, brushes) and the motor still fails, escalate to a pro or replace it to avoid hazards.

- Persistent electrical faults: repeated tripping, burning smell, or sparking — stop using it and call a certified technician.

- Severe mechanical damage: seized rotor, melted windings, or broken shaft — replacement is usually safer and more cost-effective.

- High repair cost vs. value: if parts and labor exceed ~50% of a new unit’s price, replace the appliance.

- Safety compliance concerns: aftermarket repairs without certification, water-damaged wiring, or persistent overheating — dispose and buy a compliant model.

Prioritize safety; unplug before inspection and don’t attempt high-voltage repairs.

Also, follow simple preventive steps like load wisely to reduce the chance of future motor failure.

Frequently Asked Questions

Can a Faulty Blade Assembly Cause Motor Failure Without Burning the Motor?

Yes — a faulty blade assembly can stall or overload the motor without burning it; you’ll feel resistance, hear strain, and see reduced performance. Disconnect power, inspect for jammed/bent blades, replace damaged parts, and test safely afterward.

Do Different Brands Use Interchangeable Motors or Parts?

Generally no — you can’t assume interchangeability. Brands differ in motor specs, mounts, wiring, and safety features; always check model-specific part numbers, service manuals, or consult the manufacturer to ensure correct, safe replacements and repairs.

Will Running the Grinder With a Low-Voltage Stabilizer Help Motor Longevity?

Yes — using a low-voltage stabilizer can help. It prevents undervoltage stress, reduces overheating and wear, and keeps torque stable; choose one rated for motor startup current and ensure proper grounding to maximize safety and longevity.

Are There Eco-Friendly Disposal Options for a Dead Mixer Grinder?

Yes — you can recycle appliances through municipal e-waste programs, authorized recycling centers, or producer take-back schemes; dismantle for hazardous components, drain fluids safely, label any batteries, and use certified recyclers to ensure compliant, eco-friendly disposal.

Can Warranty Transfers Happen if I Sell the Appliance?

Usually no — warranties are nontransferable unless the manufacturer explicitly allows assignment. You’ll need to check the warranty terms, get written confirmation for any transfer, and ensure the new owner registers the product to keep coverage valid.